Because of the powder bed setup, there is no need for support material, as the powder acts as the support. For one, this method allows for the printing of objects featuring any of over one million different colors. The company has made it a point to elaborate on the benefits that this technology can provide over other 3D printing techniques. Print Material: Clear Curing Agent, Powder, Clear Binder.The machine, which stands at over 5.5 feet tall, features the following specifications: The team claims to have been working on their ‘magic’ molding powder as well as the technology behind the 3D Pandoras for six years, before finally getting everything just right for a Kickstarter launch. Once the print has finished, it is soaked in the curing liquid in order to provide it with more strength. At this point, the roller comes by again, and the process repeats, layer-by-layer until an object is completely fabricated.

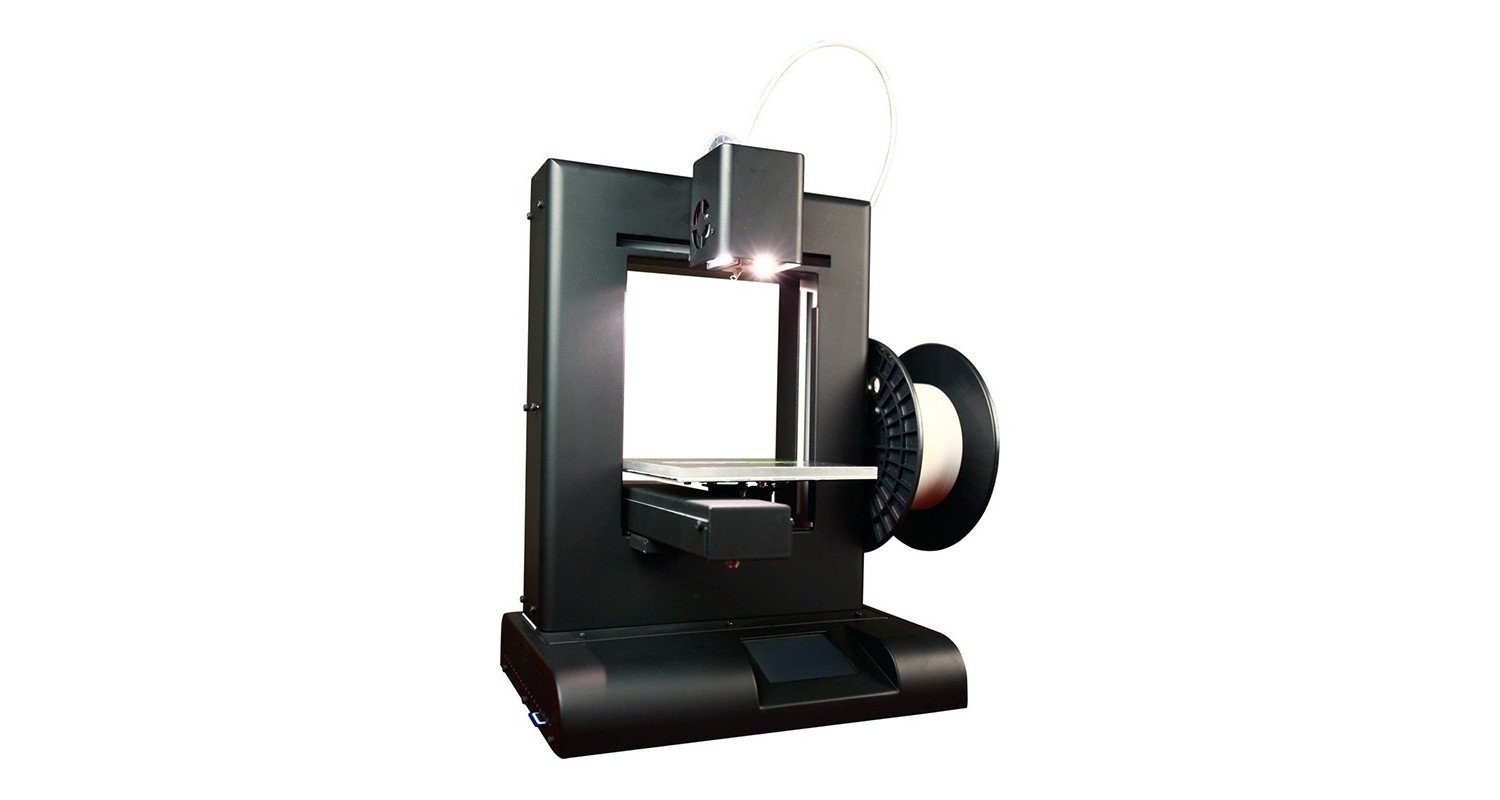

A roller places their proprietary powder on a bed, and then the print head comes by and deposits a binding agent, along with color. Way to that of a powder based selective laser sintering machine, without the laser of course. The machine, which uses a powder material, along with a binding and curing agent, functions in a similar This isn’t all for the today’s excitement though.Įl Monte, California based Global Trend Trading Technology, has just launched a Kickstarter campaign for the 3D Pandoras printer. Yesterday, we reported on Ord Solutions’ new hybrid paste/plastic 3D printer, and earlier today MakerMex unveiled their new modular 3D printer. Over the course of the last few days, we have seen several interesting new 3D printers emerge, all using new technologies, straying from the basic FDM-based extrusion models we are used to. This has been a very exciting week if you are a 3D printing enthusiast.

0 kommentar(er)

0 kommentar(er)